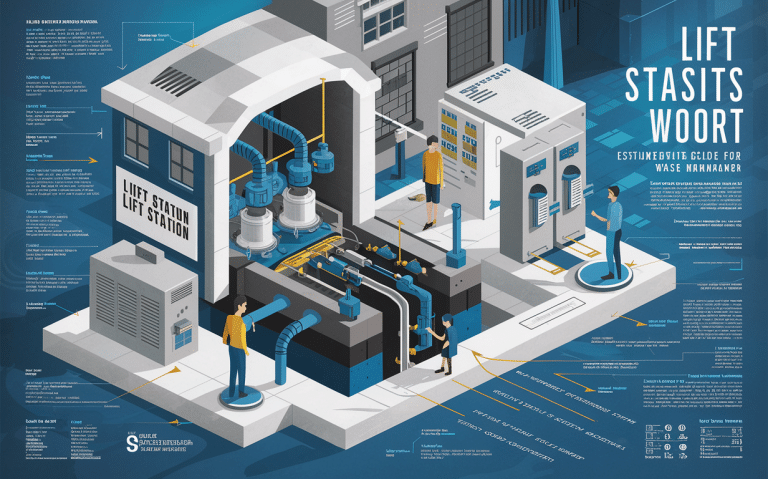

Understanding Lift Stations: Essential Guide to Wastewater Management

Understanding Lift Stations: Learn how pumps, wet wells, and SCADA systems ensure efficient wastewater management and prevent system failures.

Lift stations play a crucial role in managing wastewater in areas where gravity alone cannot handle the job. These systems are indispensable for maintaining public health and ensuring efficient wastewater management.

Key Takeaways

- Lift stations are essential for transporting wastewater from lower to higher elevations.

- They comprise key components like pumps, wet wells, and control panels.

- Regular maintenance is critical to prevent blockages and system failures.

- Sensor-based monitoring and SCADA systems can significantly enhance lift station management.

- Costs involved in lift station maintenance and repair can vary based on system complexity and issue severity.

What is a Lift Station?

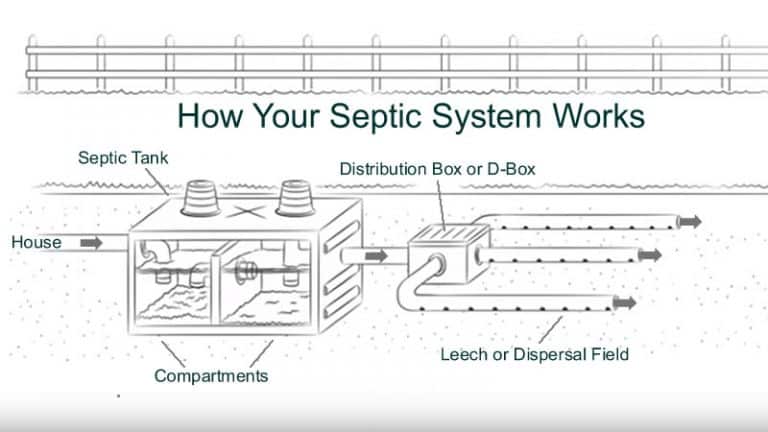

A lift station is a system designed to pump wastewater from lower to higher elevations, especially when the natural slope does not allow for gravity flow. This system ensures the continuous movement of sewage from residential, commercial, and industrial areas to wastewater treatment facilities.

Understanding Lift Stations: How It Works

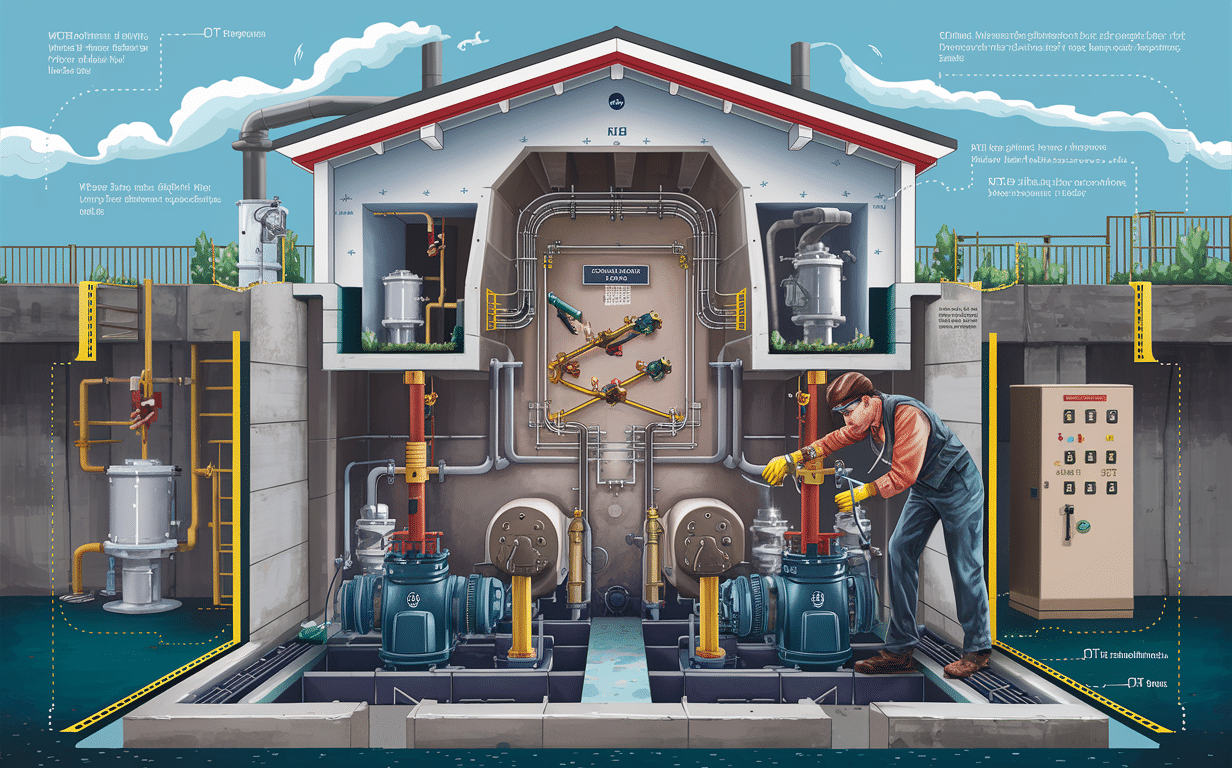

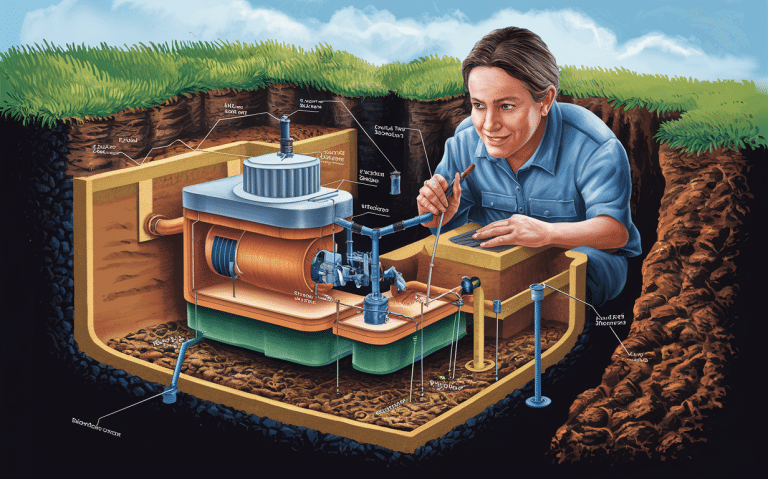

Lift stations are an essential component of sewage systems, designed to transport wastewater from lower to higher elevations when gravity alone is insufficient. They operate through a combination of pumps, valves, and electrical systems:

- Wastewater enters the lift station’s wet well, a large basin designed to hold sewage temporarily. This allows for the collection and storage of wastewater before it is pumped.

- Sensors monitor the wastewater levels within the wet well. These sensors are typically float switches or pressure transducers that detect when the water level reaches a predetermined point.

- When the water reaches a certain level, as detected by the sensors, pumps are automatically activated. These pumps are typically centrifugal or positive displacement pumps, designed to handle wastewater efficiently.

- The pumps then move the wastewater through pressurized pipes to higher elevations or directly to a treatment plant. The pressurized pipes, also known as force mains, transport the wastewater against the force of gravity.

- Valves are installed at various points in the system to regulate the flow of wastewater and prevent backflow. Check valves, gate valves, and air release valves are commonly used.

- Electrical systems power the pumps, sensors, and control systems. These systems are designed to be reliable and often include backup power sources, such as generators, to ensure continuous operation during power outages.

Components of a Lift Station

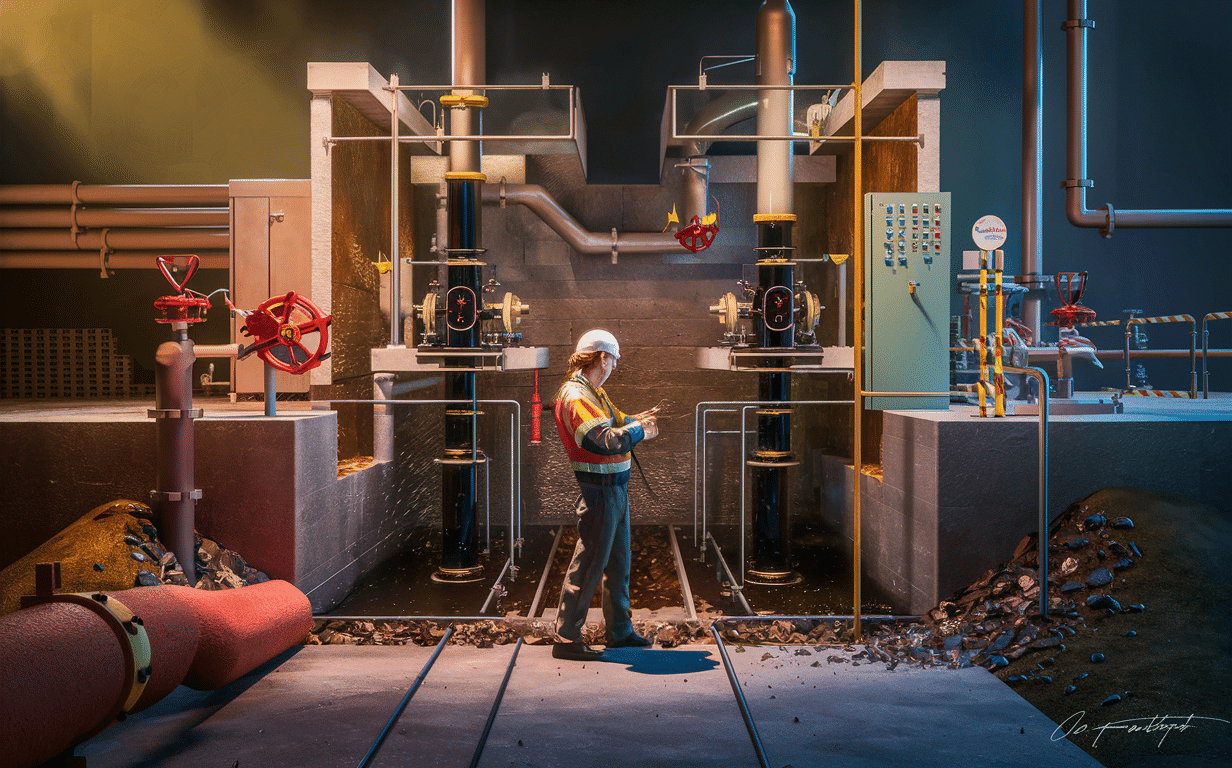

Pumps

The heart of a lift station, pumps are responsible for moving wastewater. There are mainly two types of pumps used:

- Centrifugal Pumps: Ideal for smaller lift stations.

- Submersible Pumps: Designed for larger, more complex systems.

Wet Well

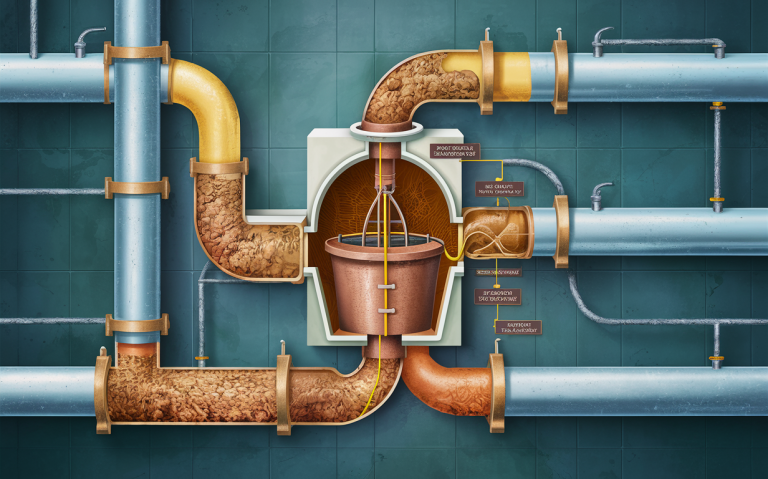

A sewage holding tank, also known as a septic tank, is a crucial component of a wastewater treatment system. It serves as a primary treatment stage where solid waste is separated from liquid waste through settling and anaerobic digestion processes.

The tank is designed to collect and temporarily store wastewater from residential or commercial buildings before it undergoes further treatment or is discharged into a sewage system.

These tanks are typically equipped with various sensors to monitor and maintain optimal operating conditions. Some common sensors include:

- Level sensors: Measure the sewage level within the tank to prevent overflows and ensure efficient operation.

- Sludge sensors: Detect the accumulation of sludge (solid waste) at the bottom of the tank, indicating the need for periodic desludging.

- Effluent quality sensors: Monitor the quality of the treated wastewater, such as pH, turbidity, or dissolved oxygen levels, before discharge.

- Leak detection sensors: Identify potential leaks in the tank or associated piping to prevent environmental contamination.

The data collected by these sensors is often integrated into a monitoring system, allowing operators to track the tank’s performance, schedule maintenance, and ensure compliance with environmental regulations. Regular maintenance, such as desludging and cleaning, is essential to maintain the tank’s efficiency and prevent potential health and environmental hazards.

Valves

These regulate the flow of wastewater and prevent backflow, ensuring smooth operation:

- Backflow preventers: These devices are installed at the point where the wastewater system connects to the municipal sewer system or septic tank. They prevent sewage from flowing back into the building, which can cause contamination and health hazards.

- Valves: Various types of valves, such as gate valves, check valves, and ball valves, are used to control the flow of wastewater within the system. They can be opened or closed to direct the flow or isolate sections for maintenance.

- Vents: Vent pipes are installed to allow air to enter and exit the wastewater system, preventing the formation of vacuum or excessive pressure that could impede the flow or cause damage.

- Cleanouts: These access points allow for maintenance and clearing of any blockages or obstructions within the wastewater pipes.

- Grease traps: In commercial or industrial settings, grease traps are installed to intercept and remove fats, oils, and grease from the wastewater before it enters the main system, preventing clogs and blockages.

By incorporating these components, the wastewater system can operate efficiently, prevent backups or overflows, and ensure the proper disposal of wastewater while protecting public health and the environment.

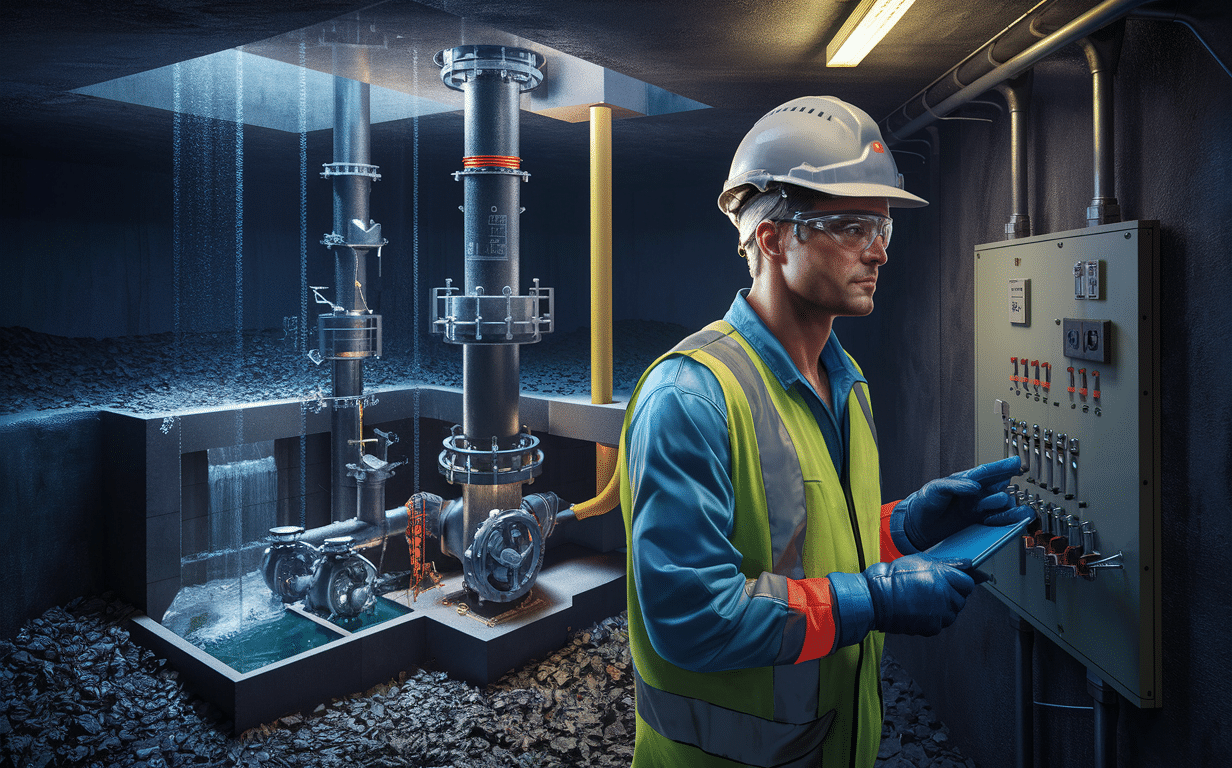

Maintenance of Lift Stations

Regular maintenance is crucial for the efficient operation of lift stations. Key maintenance activities include:

- Pump Inspections: Checking for wear and tear.

- Wet Well Cleaning: Preventing sediment buildup.

- Sensor Calibration: Ensuring accurate wastewater level measurements.

- Valve Checks: Ensuring they are functioning correctly.

Maintenance Schedule

| Maintenance Activity | Frequency | Key Checks |

|---|---|---|

| Pump Inspections | Monthly | Wear and Tear, Seal Integrity |

| Wet Well Cleaning | Quarterly | Sediment Buildup, Odor Control |

| Sensor Calibration | Bi-Annually | Accuracy, Response Time |

| Valve Checks | Annually | Functionality, No Leaks |

Common Problems in Lift Stations

Blockages

Debris and non-biodegradable items can block pumps and pipelines.

Mechanical Failure

Wear and tear of pumps and motors can lead to breakdowns.

Electrical Issues

Power failures and faulty wiring can disrupt operations.

Sensor Malfunctions

Inaccurate readings can lead to overflows or dry runs.

Emergency Preparedness

- Backup Generators: Ensure continuous operation during power failures.

- Redundant Pumps: Providing a backup pump for critical systems.

- Remote Monitoring: Using SCADA systems for real-time monitoring.

- Regular Training: Keep staff updated on emergency procedures.

- Spare Parts Inventory: Stock essential spare parts for quick repairs.

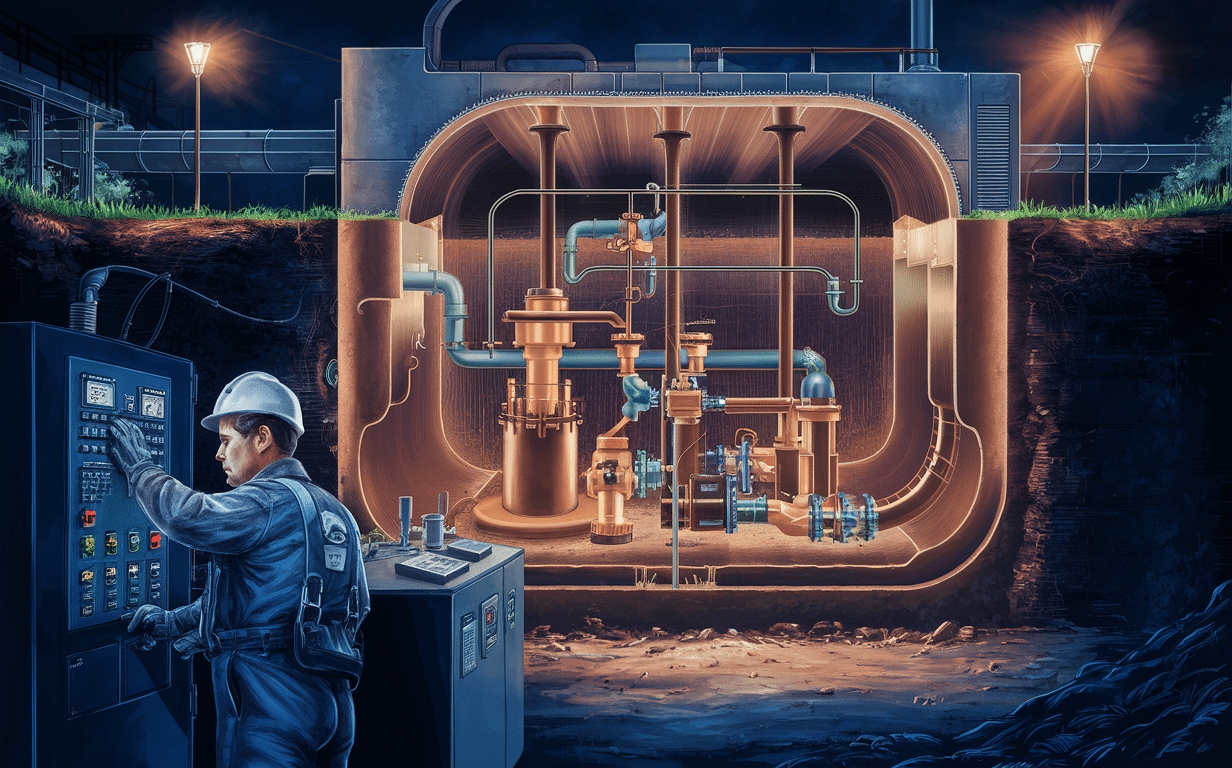

The Role of SCADA in Lift Stations

Supervisory Control and Data Acquisition (SCADA) systems are increasingly used in lift station management. SCADA systems offer:

- Real-time Monitoring: Continuous tracking of system performance.

- Data Logging: Historical data storage for trend analysis.

- Alarm Management: Immediate notifications for anomalies.

- Remote Control: Ability to manage systems from a distance.

SCADA System Features

| Feature | Benefit | Application |

|---|---|---|

| Real-time Monitoring | Immediate Issue Detection | Continuous Performance Tracking |

| Data Logging | Historical Data Analysis | Trend Identification |

| Alarm Management | Prompt Issue Notification | Quick Response to Anomalies |

| Remote Control | Access from Anywhere | Flexible Management |

Cost Considerations for Lift Stations

Initial Installation

The cost of installing a lift station varies based on complexity, location, and size. Smaller systems may cost a few thousand dollars, while larger, more complex systems can run into the tens of thousands.

Maintenance Costs

Regular maintenance is essential but can be expensive. Budgeting for routine inspections, cleaning, and part replacements is necessary.

Repair Costs

Unexpected repairs can be costly. Having a contingency fund for emergency repairs can help manage these expenses.

Expert Tips for Efficient Lift Station Management

- Schedule Regular Inspections: Prevent small issues from becoming big problems.

- Use High-Quality Components: Invest in durable pumps and sensors.

- Implement SCADA Systems: Enhance monitoring and control.

- Train Your Staff: Ensure your team is well-versed in the operation and maintenance of lift stations.

- Plan for Emergencies: Have a robust emergency response plan in place.

Key Takeaways

Lift stations are critical for efficient wastewater management. Understanding their components, maintenance requirements, and the benefits of modern monitoring systems can help ensure their smooth operation.

Investing in high-quality parts, regular maintenance, and advanced monitoring solutions like SCADA can save time, money, and prevent potential environmental hazards.

By taking these steps, communities and businesses can ensure a reliable and efficient wastewater management system. Get a FREE estimate from us today!